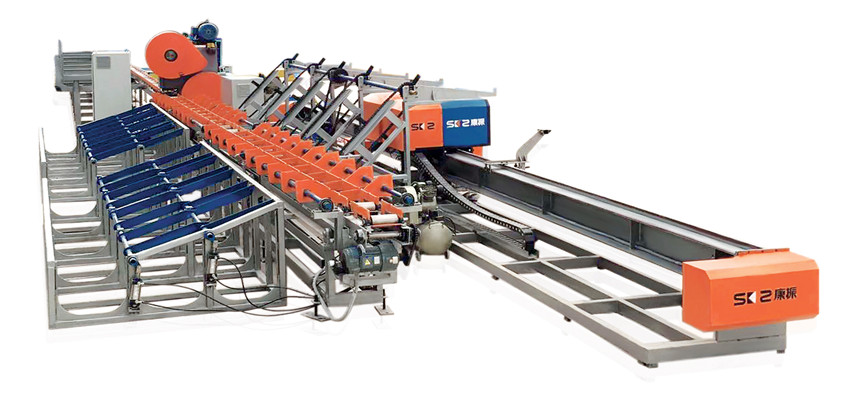

First, product introduction

This machine is a numerical control multifunctional hoop bending machine, which integrates three functions: straightening, bending and cutting. The steel bar is bent and formed at one time. It has the characteristics of less auxiliary labor, fast processing speed, high precision, high processing efficiency and long service life. It is a high-tech product with independent intellectual property rights independently developed by our company. This equipment is the first in China and fills the domestic technical gap. This machine needs to be matched with a multi-point support rack for feeding. The multi-point support material rack is another patented product developed by our company alone in response to the actual needs of the domestic construction market. The feed rack delivers steel bars smoothly, is easy to install, and is easy to use. It reduces the difficulty of adjustment when straightening steel bars, prolongs the service life of the straightening mechanism, and improves the straightening effect of steel bars. In short, our products are close to the market, strive to diversify, meet user needs, are simple and effective, and reduce costs and bring benefits to users.

Second, the use of this machine must pay attention to the following matters:

1. Equipment must not be stored and used in the open air. It must be used indoors or in a shed. There are no corrosive, flammable or explosive gases nearby. No high-voltage wires and radio interference sources.

2. It should be used, maintained, and kept by a dedicated person, and requires specialized training to be familiar with machine performance.

3. The processed steel bars should comply with the relevant provisions of GB/T 701-1997 (round steel bars) and 1499.2-2007 (hot-rolled ribbed steel bars) to ensure good processing results.

The operating temperature should be between -5 and 40 degrees Celsius, and the relative humidity should be between 20% and 80% RH.

5. Equipment used at altitudes below 1000 meters.

6. Storage environment requires dry and ventilated, temperature -20-60 ° C.

7. Electricity conditions should comply with relevant regulations to ensure the safety of the machine.

8. To process large-sized steel bars, the speed must be slowed down to ensure safety.

9. Do not modify the electrical control system without authorization.

10. During normal production, the inspection door and the electric control box door should be closed.

11. Do not stand directly in front of the door when opening and closing the inspection door with the cylinder.

12. Violation of operating procedures will result in machine damage and injury to the operator!